How to use silicon calcium wire correctly to ensure the process effect!

2020-03-03

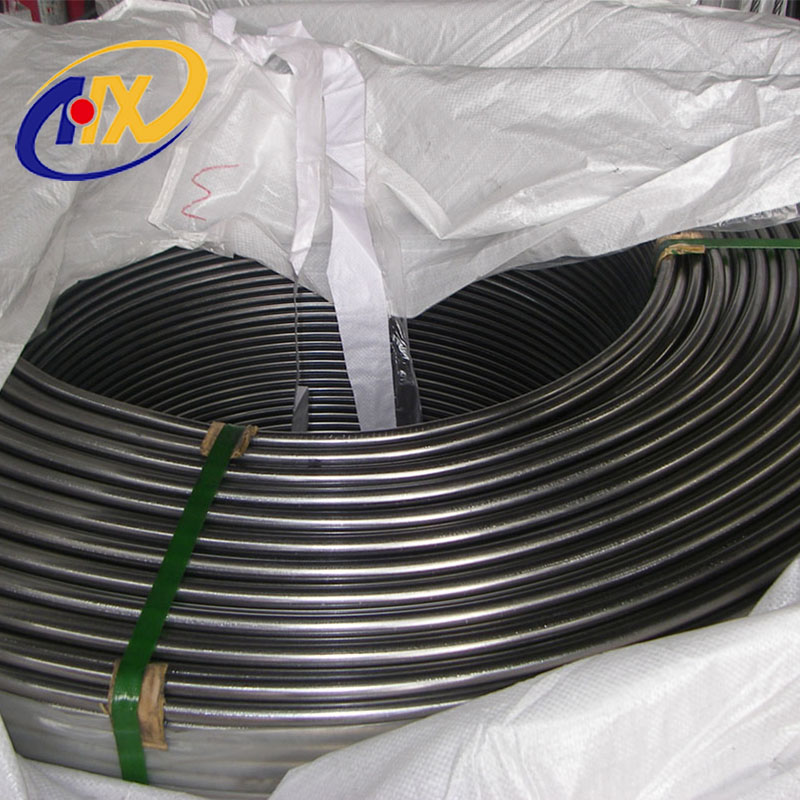

Many types of additives are added to the smelting of steel. For different additives, the effects they play are different. Silicon-calcium wire is a common additive in our lives. Other additives are different. Only in the correct way of adding ferroalloy can the function of silicon calcium wire be better played. So how to use silicon calcium wire correctly? Let's follow the manufacturers of silicon calcium wire to find out.

Solid core pure calcium wire reacts with molten steel more fiercely than silicon calcium wire during calcium treatment. Caution should be paid to the calcium treatment operations, such as feeding depth and wire feeding speed. Due to the high vapor pressure of the solid core pure calcium wire, In order to prevent the natural evaporation of calcium, solid pure calcium wire must be fed deep. One method is to increase the thickness of the iron sheet to prevent its premature melting from affecting the depth of calcium release. The other method is to increase the wire feeding speed to increase the calcium. Depth of release, high wire feed speed enables solid core pure calcium wire to penetrate the slag layer and reach a certain depth, reducing the oxidation of Ca by slag, increasing the absorption of calcium by molten steel, and improving the recovery rate of calcium.

Feeding line speed and feeding rhythm are the key parameters of solid core pure calcium line feeding process. Too fast or slow feeding speed will affect the melting time and oxidation degree of solid core pure calcium line, which will affect the metallurgical effect. The operator must pay close attention to the molten steel situation. Once the molten steel tumbles fiercely, he must pause for a while before continuing to feed the wire to prevent splashing.

Hengxing Metallurgical Materials Co., Ltd. is a professional manufacturer of ferroalloys and metallurgical materials. It has professional ferroalloys and metallurgical materials production equipment and facilities. All employees are required to accept professional knowledge of ferroalloys and metallurgical materials before they can take up their posts. Welcome everyone to consult and cooperate.